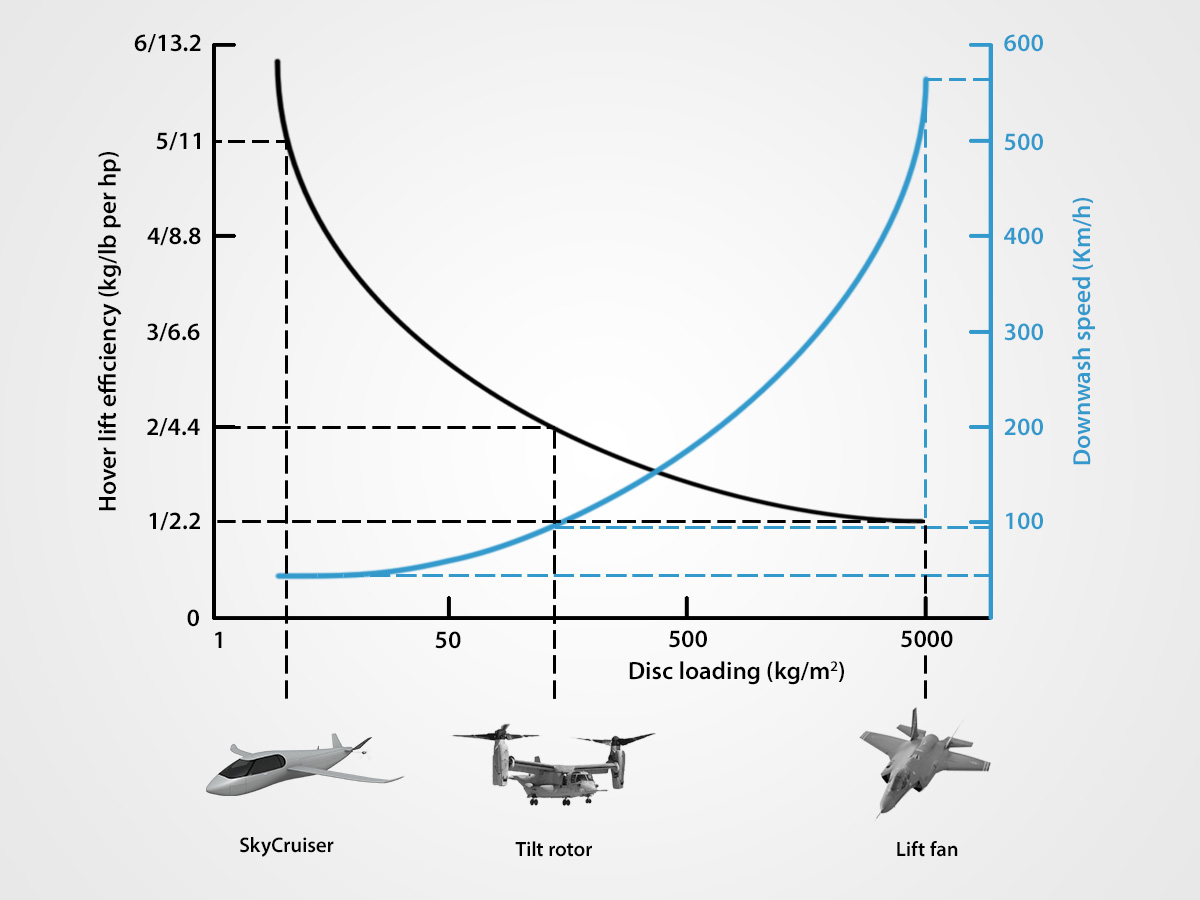

Disc Loading and Hover Efficiency

Disc loading relates the weight of an aerial vehicle (e.g. a helicopter or multicopter) with the area, called rotor disc area, that the rotor(s) sweep(s). Often it is then standardized into kg/sqm or lb/sqf.

Hover efficiency relates the weight of an aerial vehicle with the power required to keep it aloft in hover. It is usually expressed as lb/hp or kg/hp or kg/kW.

Interestingly the two measures are related, related in such a way that a lower disc loading yields a higher hover efficiency. Expressed differently, the larger the area that the rotor(s) sweep(s) the less power is required to hover. A larger rotor disc area generally means better hover efficiency.

AeroVelo Atlas human powered quadrotor with a total combined 1,300 sqm (14,000 sqf) rotor disc area. The disc area of one of the four rotors is indicated in the picture. (Wikimedia Common)

An extreme example of this is the AeroVelo Atlas shown left, a human powered quadrotor. Due to ultra-light weight construction it only weighs 128 kg (282 lb) with pilot (which can produce about 1 hp), but it has a massive disc area of almost 1,300 sqm (14,000 sqf). This is more than twice the disc area of the largest helicopter in the US military, the Sikorsky CH53 E Super Stallion, which with a maximum weight of 33,000 kg (74,000 lb) is almost 300 times more heavy than the AeroVelo Atlas. The Atlas' super low disc loading of 0.1 kg/sqm translates into a hover efficiency of 128 kg/hp. CH 53E on the other hand, with its disc loading of around 70 kg/sqm (700 times more heavily loaded than the ATLAS), requires around 10,000 hp to take off which translates into a hover efficiency of only 3.3 kg/hp. The Atlas hence has a hover efficiency around 40 times better than the Super Stallion. An even more extreme example is the F 35 Lightning. It's thrust vectoring and lift fan VTOL system has a disc area of only around 6 sqm (60 sqf) for a weight of up to 30,000 kg (66,000 lb), giving it a disc lading of around 5,000 kg/sqm, around 50,000 times more heavily loaded than the ATLAS. Consequently the F35 requires around 30,000 hp to take off, meaning that it's hover efficiency is only 1 kg/hp, 128 times less efficient than the ATLAS.

Hover efficiency versus disc loading. Lower disc loading is more efficient, meaning less power is required to hover. (Krossblade)

The general relationship between disc loading and hover efficiency is shown in the graph on the right. What a rotor basically does is to push air downwards in order to push itself upwards (Newton's third law). Broadly speaking, producing the same upwards force, it is more energy efficient to do this moving a larger volume of air downwards more slowly, than moving a smaller volume of air downwards more quickly. This also means that not only does a higher disc loading lead to lower efficiency, it also leads to more severe down wash (the air that for example a helicopter blows downwards and into the faces of onlookers) and also to larger noise from the faster moving blades and air.

So why not make helicopters with huge disc areas, thousands of square meters (tens of thousands of sqf) in order to lift off with very little power? There are several reasons:

1) Large blades make the helicopter more sensitive to wind gusts, the heli becomes less stable

2) Very large and very slowly moving blades would limit the possible forward speed to only a few kph or mph

3) Space considerations also guide helicopter design, a heli has to be able to land in small spaces and park

4) Large blades are technically more challenging to build and can get very heavy

Typically, the smaller the helicopter or multicopter the lower the disc loading. Smaller civilian helicopters are used on helipads and many other landing spots close to people, so noise and down wash are a problem and have to be kept low. It is also relatively easier to build a large rotor (relatively speaking) for a small helicopter than for a large one.

On the other extreme end, direct lift thrust vectoring and lift fan systems like the Harrier Jet and the F-35 have tiny disc areas (small nozzles and fans) and hence massive disc loading and typically require all the power of their enormously powerful jet turbine engines engines to take off and land vertically. Don't try to stand too close when one takes off, down wash velocities far exceed most severe hurricane levels (and down wash can be super heated; the Harrier, for example, is known for melting away concrete on take-off) and noise both from the engines at full power and from the rapidly moving down washed air, is absolutely ear deafening. It takes a ton of gas to get such systems off the ground and it is extremely taxing for these systems to perform VTOL because such extreme power levels are required.

SkyCruiser and SkyProwler have disc loadings that are similar to that of smaller helicopters with comparable weights (e.g. the Bell Jet Ranger or the Robinson R44) so their hover performance is energy efficient and they are fairly quiet, producing gentle down wash.